Sealcoating is a liquid that is applied to asphalt to protect it from oxidation, and the damages caused by winter cracking, as well as UV rays and traffic. Sealcoating is the key to asphalt preservation and longevity.

Our professional staff will assist you in selecting the sealer product perfect for your project.

Asphalt Maintenance

Our Services

ADA

Lorem ipsum dolor sit

Asphalt

Lorem ipsum dolor sit

Asphalt Maintenance

Lorem ipsum dolor sit

BPP Sign Off

Lorem ipsum dolor sit

Concrete

Lorem ipsum dolor sit

Masonry

Lorem ipsum dolor sit

Street Milling

Lorem ipsum dolor sit

Striping

Lorem ipsum dolor sit

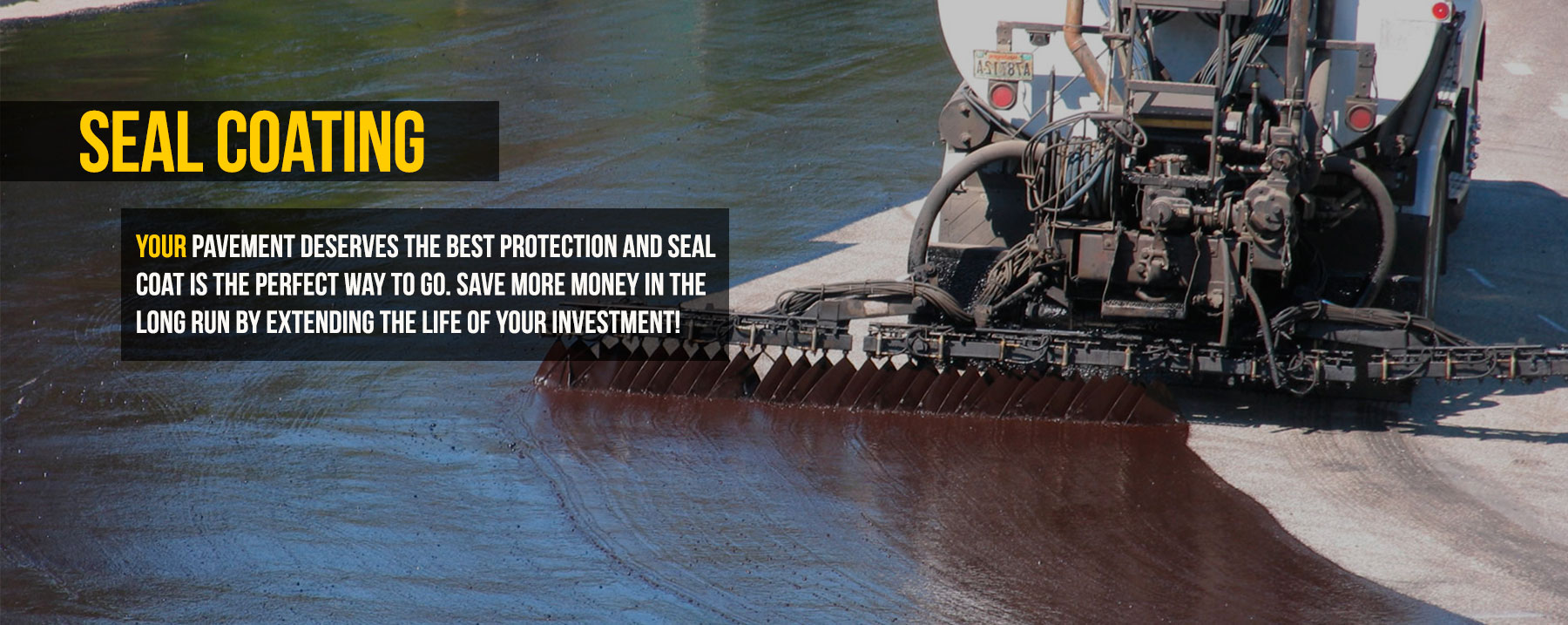

SEAL COAT SERVICES NYC

Seal Coating is an essential aspect of preserving and extending the life if your asphalt surface. Many benefits are involved including improving the visual aesthetics, protection against oxidation from the sun, replacing and repairing eroded surfaces, longer surface life and optimizing its overall value.

Other benefits of sealcoating include creating a uniform color and appearance for all asphalt paving.

CRACK FILL SERVICES NYC

Crack filling is an essential application in addition to sealcoating for long-term pavement protection.

These two maintenance steps are a cost-efficient way to get the longest life out of your pavement instead of renewal.

APPLICATION OF SEAL COATING NYC

We begin by cleaning any dust, vegetation and debris from around the crack using a high-pressure steam of air and a powered grinding wheel. Next, the crack is sealed with a hot polymer based material. The extreme heat during this application causes the edges of the crack to melt and form a stronger bond with the sealer. The sealer then expands and contracts due to the thermal movements of the crack. Because of this high melting temperature, it will track or pick up in traffic. When it has cooled, the surface is ready for a fresh seal coat re-striping and painting markings.

Doing the right thing,

at the right time.

15

LOCATIONS

100

ENGINEERS

47

PROJECTS

10

YEARS

1st free appointment, the fist step for your project

Maintained By Galvin Contracting

© Copyright 2024. All Rights Reserved